“Proactive service of Renovate Winding”

Introduction:

You definitely might have come across a critical situation, wherein your Motor, Servos, Generator, Transformer or Equipment in Panel Suddenly failed, till date it was running ok and suddenly failed, and your production is held up due to that. Now think if you would have known the upcoming failure well in advance, you would have made an alternative arrangement or could have planned the production accordingly.

What is Predictive Test (PT) or Condition Monitoring (CM).

Predictive Test is the process of monitoring a parameter of condition in machinery, such that a significant change is indicative of a developing failure. The use of conditional monitoring allows maintenance to be scheduled, or other actions to be taken to avoid the consequences of failure, before the failure occurs.

CM is the technique served for Condition-Based Maintenance (CBM) (or named as predictive maintenance). Condition monitoring is the study of methodologies to detect symptoms of possible failure in electrical equipment.

What Service We Provide

We Provide Predictive (in advance) up- coming failures/defects in your all kinds of AC/DC Motors, Servos, Generators & Transformers. A Complete Health checkup to avoid un-expected failures, i.e Maintenance with Intelligence.

Advantages of Predictive Test (PT) / Condition Monitoring (CM) .

- You can now know the failure well in advance.

- Down time of your Machine decreases.

- You have sufficient Time to search, make or procure an alternative arrangement or can plan production accordingly.

- You can now detect large failure in its Pre Stage.

- You can Rectify the same in less time and with less money.

- Healthy Relation between Production, Maintenance & Purchase Team.

- Maintenance with Intelligence.

- Enhance life of equipment

What are the Losses You can Protect

- Un-expected/Sudden Production loss.

- Excess Down Time.

- Large Amount of Money in Repairs.

- Smooth Production.

- System Stability and Reliability.

- Man Power Loss control.

- Prevention is Better than Cure.

| 90% Failure are Due to | 10% failure are due to |

| Winding Inter-turn insulation failure | Un-balance Load |

| Winding Phase-Phase Failure | Foreign Object fall inside machine |

| Winding Phase-Earth Failure | Single Phasing |

| Contamination due to carbon/grease/dust/dirt/rusting | Un-balance Voltage |

| Rotor Stator Rubbing due to bearing loose on shaft,

bearing loose in Housing. |

Over Load |

| Bearing Failure | Shaft Shearing due to jerking |

| Loose contact in connection ring inside motor | Cable Fault |

| Loose Connection on Lug or Crimping | Drive Fault |

| High Harmonics Content | Wrong Phase Sequence |

Stator Failure: 55%, Bearing Failure: 23%, Rotor & Shaft: 16%, Balance & Alignment: 6%

Phase-Phase Short

Inter-turn failure

Over Heated Winding

Rotor-Stator Rubbing Case

Phase-Earth Heavy Flash

Bearing failure, got cracked & rollers came out

We Analyze by comparing following Values

| Sr | Parameter | Faults Indicated |

| 1 | Resistance | Loose Connection on Lug /Crimping, Connection Ring |

| 2 | Tan Delta | Contamination due to carbon/grease/dust/dirt/rusting |

| 3 | Impedance | Rotor Bar Crack & Rotor Faults (in slip-ring & generator) |

| 4 | Insulation Resistance | Healthiness of Insulation in Ph-Ph & Ph-E |

| 5 | Phase Angle | Inter-turn short |

| 6 | Current/Frequency Response (I/f) | Inter-turn short |

| 7 | Test Value Static (TVS) | Immense Rotor & Inter-turn fault |

| 8 | Vibration Level | Bearing loose on Shaft, Bearing loose in Housing, Improper Alignment, loose/overtight belt. |

| 9 | Noise Detection | Faulty/Noisy Bearing, Rotor/Stator Rubbing. |

Facts about electrical & mechanical faults

- They start small & get worse; albeit (of course) not overnight.

- They always end in failure/break down of machine.

Certain conditions will aggravate them (increase them fast):

- Over loading

- Frequent start/stops

- Vibration

- Contamination

- Heat

- High harmonic content

What are Phase Angle & Current/ Frequency (I/f) Response?

- Phase Angle : The relative angle between the two vectors of the applied test voltage & drawn current

- Current/Frequency (I/f) Response: Voltage is applied to the winding at different frequencies & the change in the current drawn is assessed. It is the percentage reduction in drawn current when the voltage frequency is doubled.

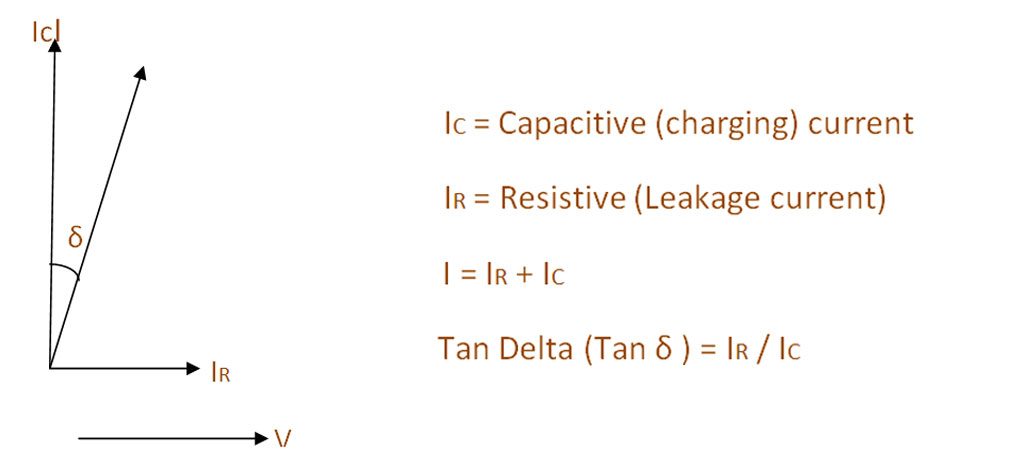

What is Tan Delta?

What is Test Value Static (TVS)?

Test Value Static is a dimensionless quantity to simply Machine circuit analysis testing.

It combines impedance, inductance, phase angle & I/F measurements to give a single value that can predict inter-turn insulation defects & rotor defects.

It is unique for each motor & is hence to be trended over time. It can also be used to compare identical motors.

Case Studies

7.5 MW, 11KV, 1500 RPM Alternator.

Was running on 93% load with electrical, mechanical and thermal parameters well within limit.

During PT/CM detected the problem, When Dismantled the Alternator we found White Metal/Sleeve Bearings was 60% damaged, got detected in very pre stage. Protected large bearing replacement cost and Rotor-Stator Rubbing.

300 KW, 6.6 KV, 1500 RPM Motor was running on full load with electrical, mechanical and thermal parameters ok.

In PT/CM found Stator winding “Warning” alarm due to contamination, when dismantled motor found grease spread all over winding.

2500 KVA, 11 KV/433 Volt Transformer, Inter-turn Problem.

Was charged on 75-80% load.

In PT/CM found ‘B’ phase winding “Warning” alarm due to inter-turn, when dismantled Transformer Found inter-turn insulation weak and about to fail anytime

870 KW, 11 KV, 2987 RPM Motor, Rotor Bar Damage .

Absolutely running smooth with overall vibration less than 2.3mm/sec pk-pk, No temperature rise or abnormal noise.

During PT/CM detected the problem of rotor bar crack. Attended the problem immediately & during visual inspection found 7 rotor bars were broken.

Client than protected further failure.

550 KW, 2985 RPM, Compressor Coupled, LT Motor.

During PT/CM detected the problem of weak phase to Earth. Customer could not take shut down, but mean while arranged for spare motor & got it replaced within few hours shut down.

Had the motor not been tested, it could have failed shortly and lead a long break-down of entire unit.

720 KW, 690 volt Slip-Ring Induction Motor.

In regular PT/CM predicted a severe rotor fault, No significant action was taken by client.

The rotor Failed within a month. The Flash was such a severe that it also damaged Stator Winding.

The Plant was Shut-Down for nearly a month till the motor could be repaired.